Muphfince

Repository to store the codes used in research of MUltiPHase Flows IN Chemical Engineering (MuPhFInCE)

Project maintained by MartinIsoz Hosted on GitHub Pages — Theme by mattgraham

MuPhFInCE

Repository to store the codes used by the MUltiPHase Flows IN Chemical Engineering (MuPhFInCE) research group of the University of Chemistry and Technology in Prague (UCT Prague).

The principal aim of the repository is to share the case settings and utilities between the group members. Our main tools are OpenFOAM, Paraview and Python.

Research motivation and background

Research motivation

Multiphase flow is of great importance in many chemical engineering applications. As examples, we may mention a description of hydrodynamics in absorption and distillation columns or bubble column reactors.

In our research, we focus mainly on the first of the listed processes. More specifically, we are aiming at modeling the flows with the utmost importance of the interfacial area size. Hence, the direct application of our work can be found in designing the above mentioned separation columns.

Background

A few notes on a structured packing and on a liquid flow on it.

Liquid flow on a structured packing

- Column diameter: 15 cm

- Packing: Mellapak 252Y.

- System: Water-steel-air

- No gas flow

- Moderate liquid flow rate

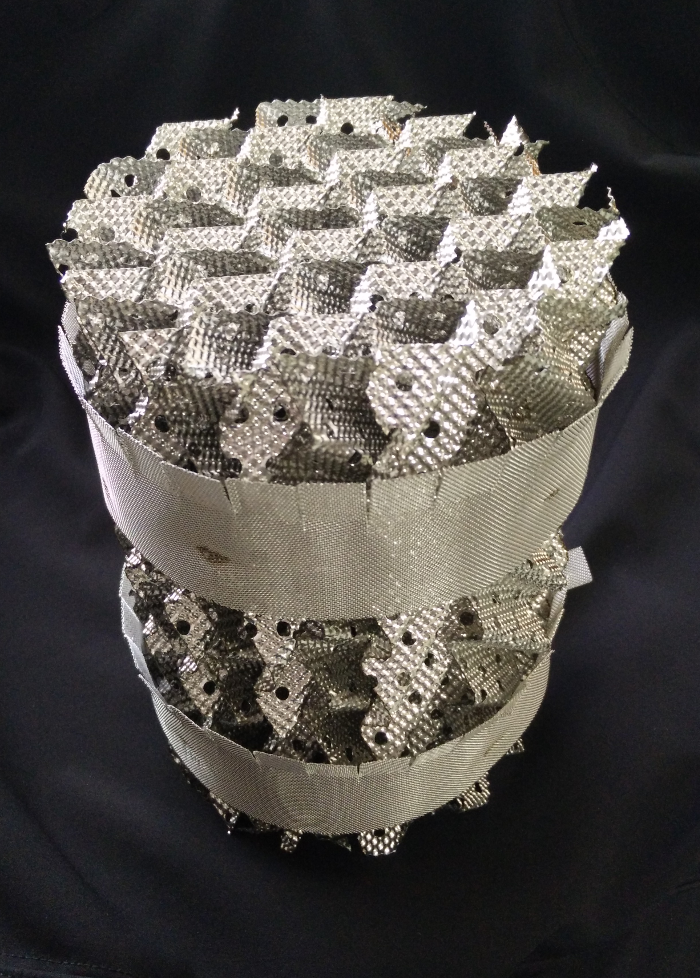

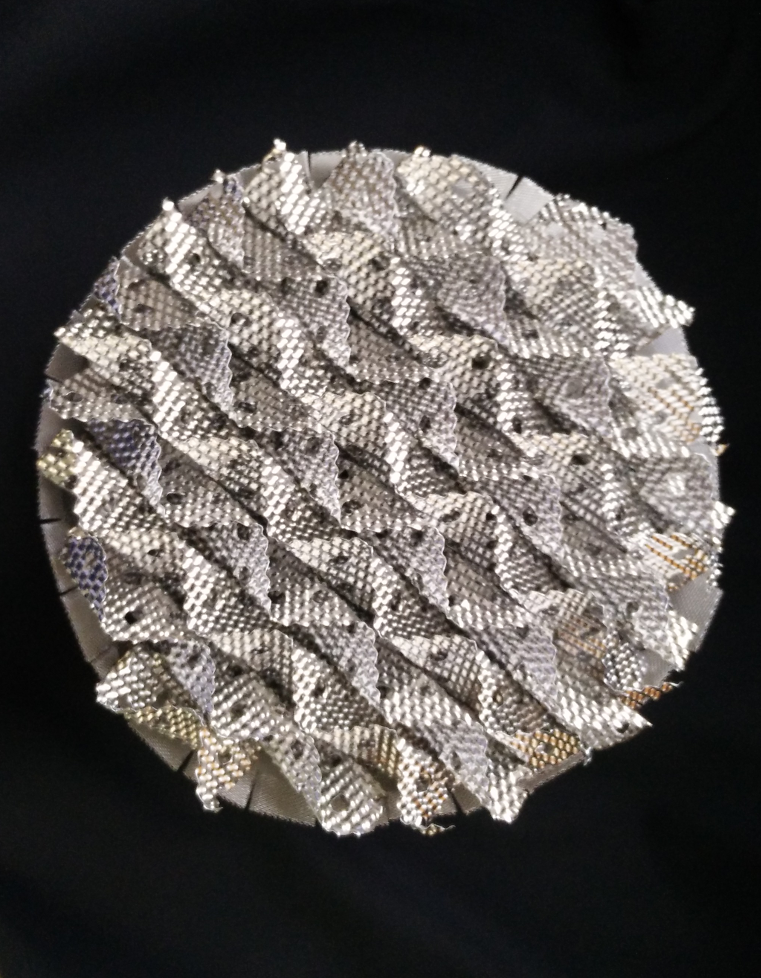

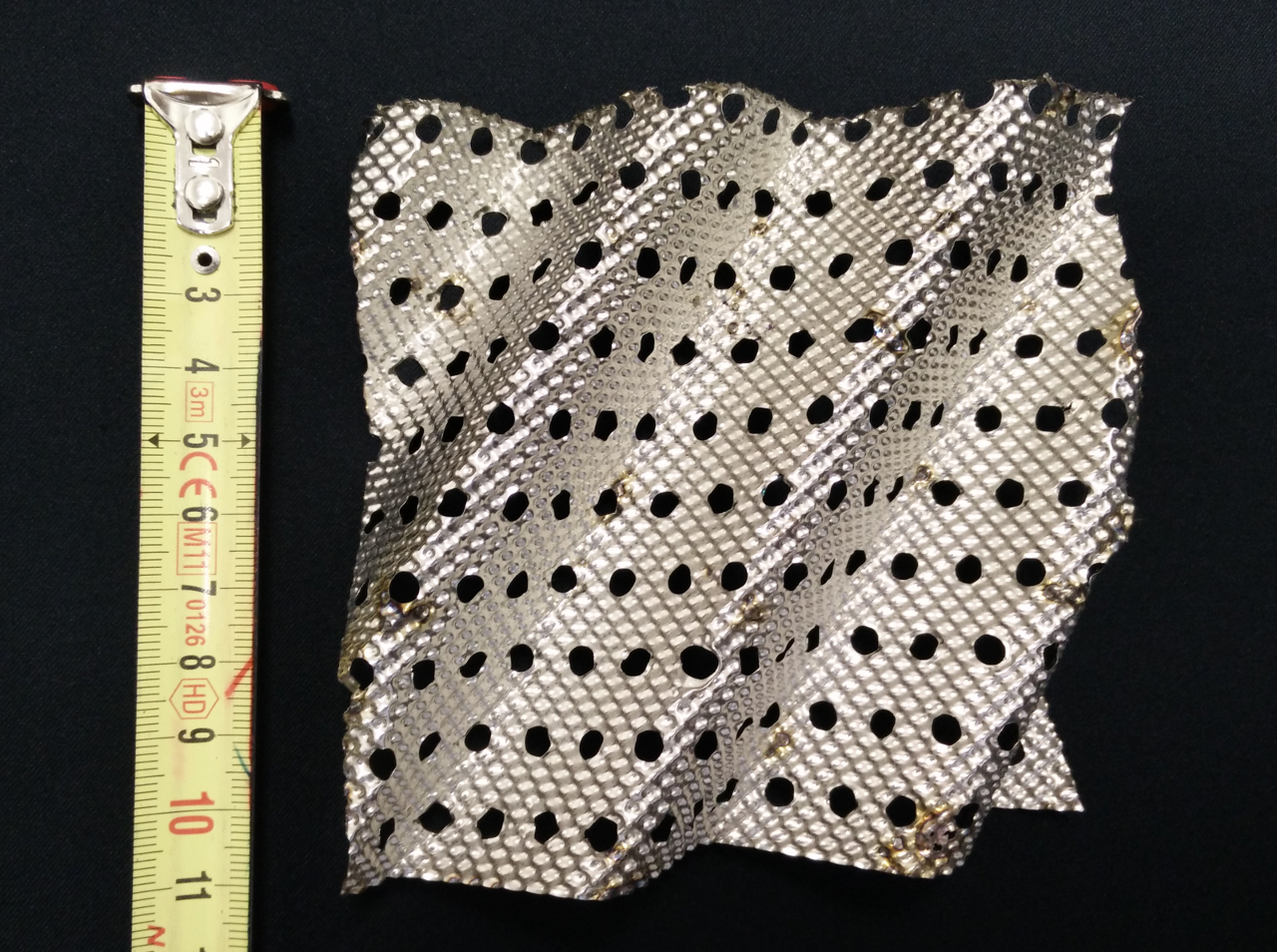

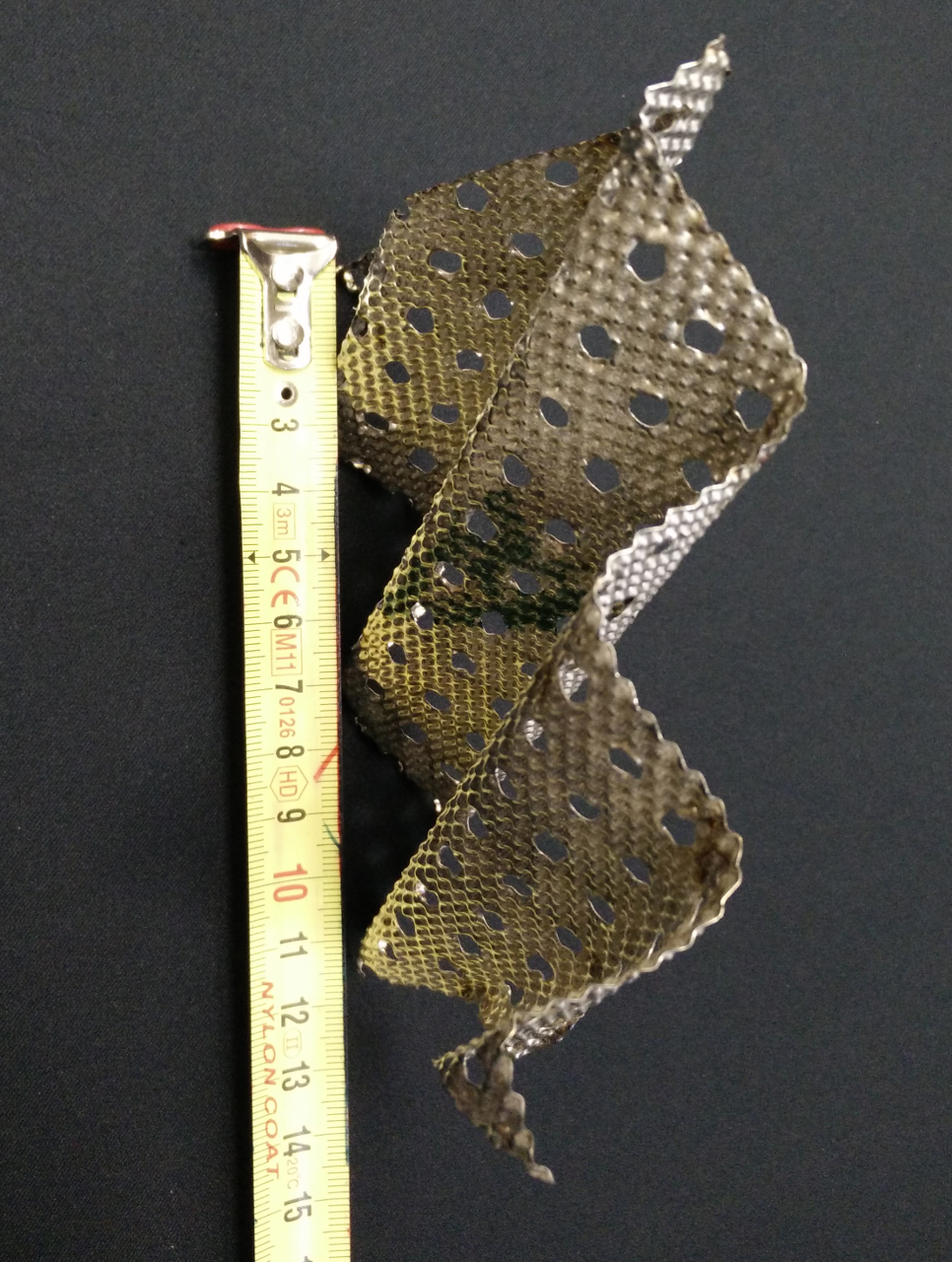

Structured packing

- Complex structure

- Composed from curled, textred, perforated plates

- Various materials (yet steel is the most used one)

|

|

| Overall view of Mellapak 252Y packing | Top view of Mellapak 252Y packing |

|

|

| Front view of a dismantled packing | Top view of a dismantled packing |

Our approach to the problem

Separation columns, apparatuses used in chemical engineering to perform the mass transfer operations in large scales, host a complex set of physical processes including heat and mass transfer and multiphase flow. Even with the continuous development of computational fluid mechanics (CFD) methodology and the lasting growth of available computing power, the direct modeling of processes in packed columns is still an open issue. To develop a direct numerical simulation of a packed column, one would have to simultaneously solve the balance equations for momentum, mass, energy and the present species, all of which completed by a reliable model of mass and heat transfer across the interface. From a mathematics point of view, such a model would have to consist of (at least) six partial differential equations and several algebraic equations defined on a complex domain forced by the packing geometry.

Because of the aforementioned complexity, it is a common practice to study the processes occurring in packed columns on simplified surrogate models. One of the currently most common approaches is to reduce the geometrical complexity of the column packing and to approximate a small part of it by an inclined plate. Thus, the properties of interest (hydrodynamics, heat and mass transfer) are studied in a simple cuboid geometry.

Cooperations

As the nature of our work would suggest, we closely cooperate with the Mass transfer group of UCT Prague as well as with the CFD Laboratory of UCT Prague (cs).

General description of the studied problem

- Problem category: Multiphase (Free surface) flows

- Solution methodology:

- Low Reynolds numbers in both liquid and gas phases -> Incompressible fluids

- OpenFOAM solver -> Finite Volume Method (FVM)

- Simple geometries -> (mostly) structured hex meshes

- Multiphase solution method -> Volume of Fluid (interFOAM solver)

- Challenges:

- Liquid spreading is of utmost importance

- The problems are transient

- The processes are multi-scale (length and velocity scales in the main flow direction differs from the ones defining the spreading dynamics)

Droplet spreading

Motivation

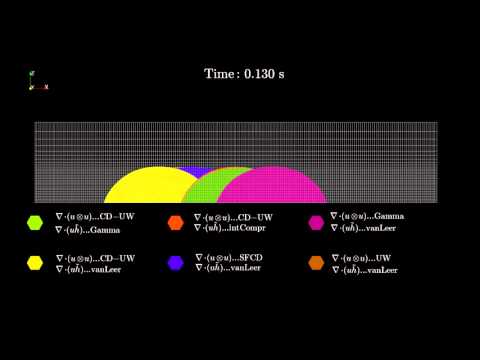

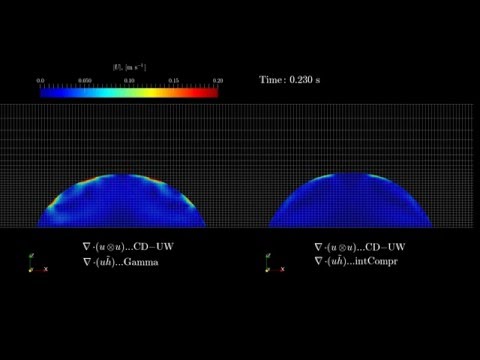

The quality of the solution for spreading flows depends heavily on the accuracy of the description of the spreading. Hence a simple case of a liquid drop spreading on a horizontal substrate was taken as a benchmark situation and several different discretization schemes were thoroughly compared.

Results

Unphysical behavior of some discretization schemes

Parasitic currents in the solution

Relevant repository directories

Liquid flow down an inclined plate

As it was mentioned before, the most widely employed approximation of packing geometry is by an inclined plate. Such an approximation enables a study of the hydrodynamics of fluid flows in both macro- and microscopic regimes.

The presented codes are divided in three sections corresponding to the surface treatment of the inclined plate. The initial and benchmark simulations were performed for the case of a smooth plate. Later on, extensions for the cases of a plate equipped with a longitudinal, transversal or pyramidal texture were added.

Smooth plate

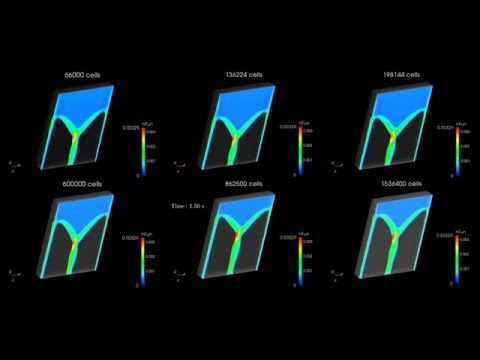

Mesh size optimization

Resuls for different liquid flow rates

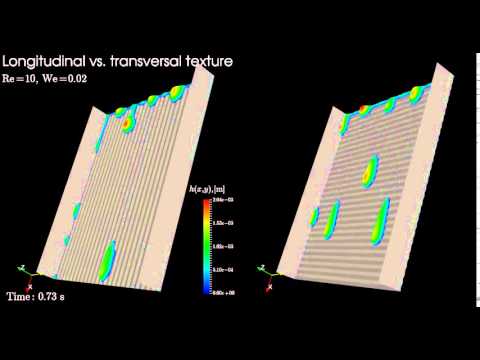

Textured plate

Flow on different texture types

Longitudinal texture

Transversal texture

Pyramidal texture

Wetted to total area ratios in dependence on the flow Weber number

Relevant repository directories

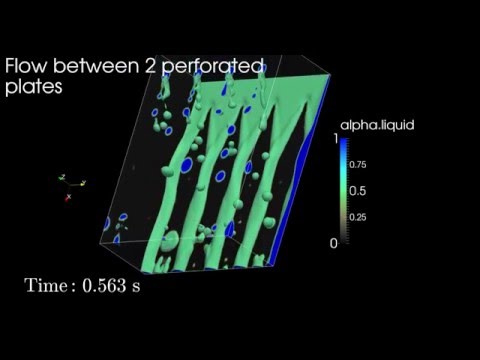

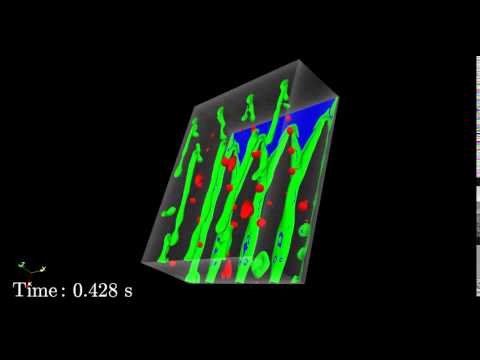

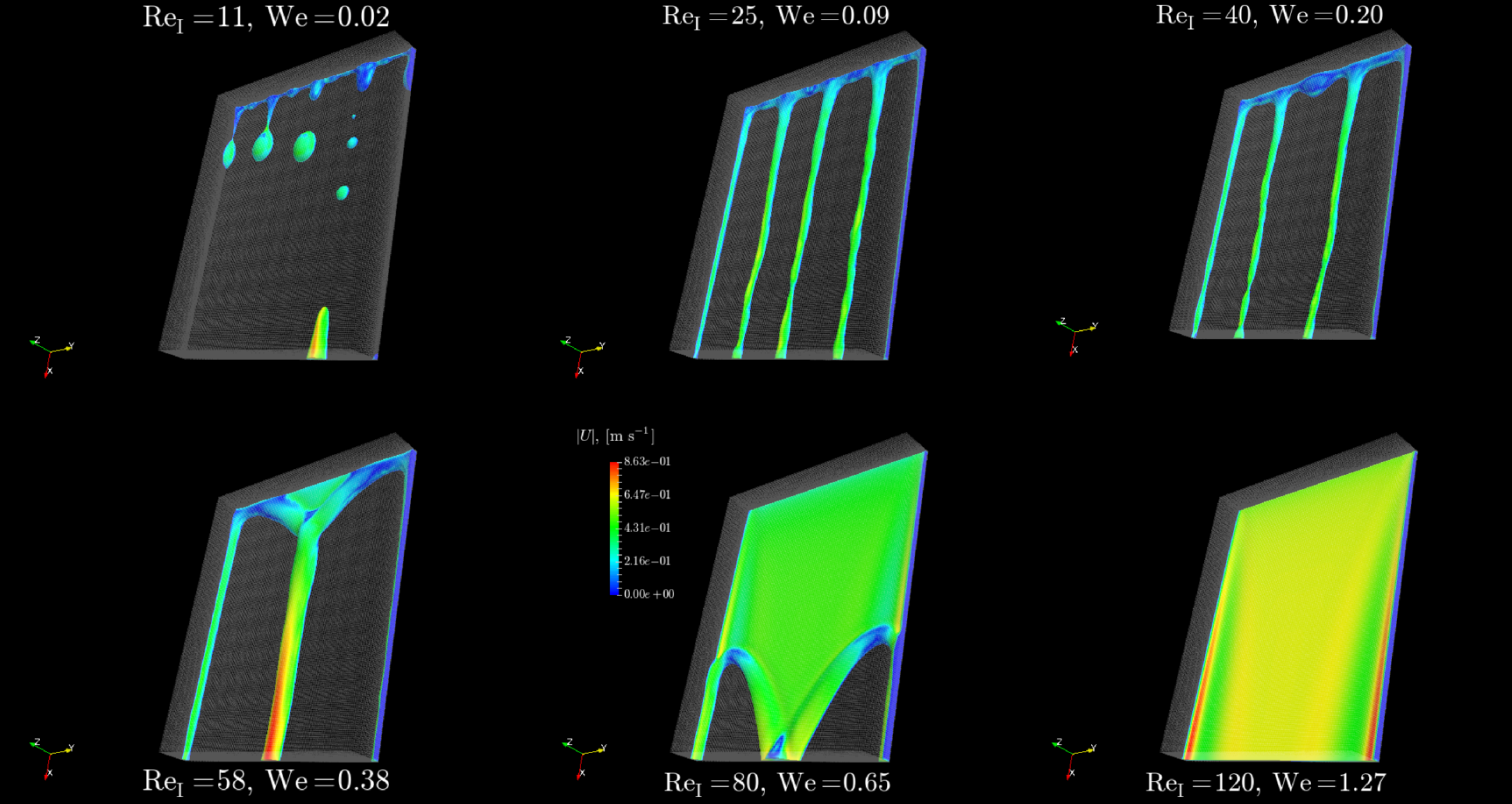

Liquid flow between two perforated plates

The column packings usually consist of perforated metal sheets. To examine the liquid behavior between such sheets a simulation of a flow between two perforated plates was performed.

Usually, it is assumed, that the liquid is flowing in a film flow regime both on the bottom and under the top plates. Hence, an emphasis was made to distinguish between the different flow regimes.

Overall transient simulation of a flow between two plates with uniform perforation

- Problem Weber number: 4.04

- Problem Reynolds number (at inlet): 240

Flow regimes distinction for a flow between two plates with zig-zag perforation

- Problem Weber number: 4.04

- Problem Reynolds number (at inlet): 240

- Green - rivulets, Red - drops, Blue - film